Our Products

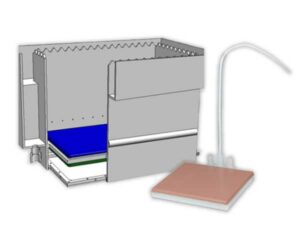

PCT specializes in providing end-users and OEM’s customized solutions for their particular needs. PCT can design and provide customized equipment for megasonic assisted tools and transducers, heated tanks, R&D sized tools and Megasonic or Ultrasonic standalone wet benches.

PCT specializes in supplying custom solutions for your application.